Challenge

A long-standing customer of Sewtec requested our help to provide a bespoke automated solution that would pack and seal closed their tobacco products quickly for optimum preservation.

Invention

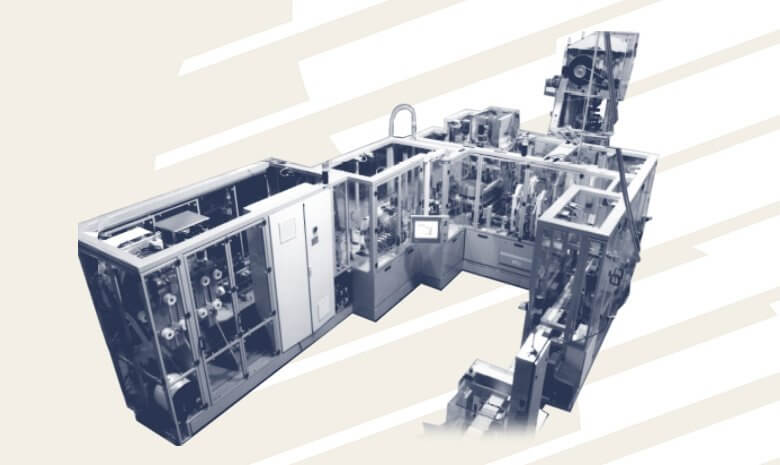

Our engineering team engaged with the customer to provide an automated tobacco packaging machine that would create, fill, and close a pouch. At the same time, we modified and integrated two high-accuracy weighers and a weight-check metal detector. Transfer conveyors were adopted to move the filled pouches to a carton packing machine or, via a second leg, to a flow wrapping machine.

Results

The system is a success, feeding the tobacco through a bucket conveyor system, into its pouch, and sealed close at a rate of 120 products per minute.