Automated product testing and inspection

From metal detection to product verification, an array of tests and processes may need to take place before a product can enter the supply chain.

Automating essential product verification processes using industrial vision systems is vital for any manufacturer looking to maximise Overall Equipment Effectiveness (OEE).

The importance of industrial vision systems

Industrial vision systems are key to automated product testing and inspection and ensure high quality across manufacturing. From 1D and 2D code verification used in the track and trace or serialisation arena, to application-specific 2D and 3D quality checks which uncover any defects, an industrial vision system holds the key to consistently delivering a quality product for any industry.

By including an intuitive user interface, industrial vision systems can provide full visibility of each test as it occurs, highlighting live results at the point of manufacture.

Automated product testing and inspection systems by Sewtec Automation

Our specialist team of industrial automation integrators and in-house software engineers are highly skilled in designing and installing product testing, inspection, and verification systems to achieve the highest possible quality of a finished product.

Thanks to our extensive knowledge of third-party cameras, we can integrate high-quality hardware with specialist software written by Sewtec Automation to maximise the effectiveness of the testing and inspection processes. The result is an automated testing or verification system integrated at the core of your production line.

Automated product testing and inspection components

Our specialist product testing and inspection systems are created from an extensive list of core components.

Our industrial vision systems are responsible for recognising parts and performing essential quality checks. Our experience of pairing the best vision systems on the market with specialist software written by our in-house software engineer means we can enable a vision system to perform any task, no matter how complex.

With the traceability of products a growing requirement for manufacturers in many industries, our code readers can scan and record barcodes or other visual product data to ensure a product meets your predetermined requirements before leaving your line.

For critical components used in the medical devices industry, safety and reliability cannot be compromised. Our electrical testing capabilities ensure you can be confident of your devices’ reliability as soon as they are connected to a power source in a healthcare environment.

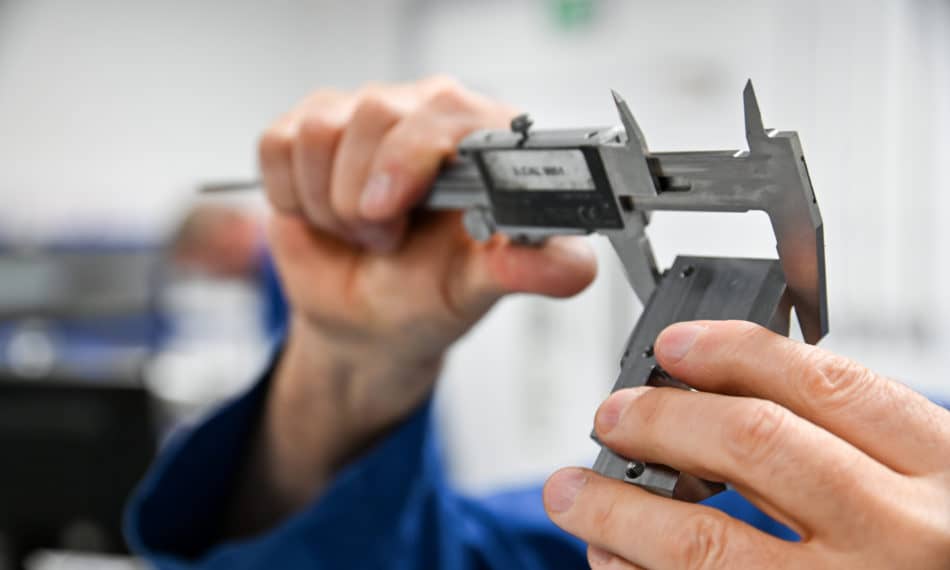

By relying on laser micrometre technology, our automated product verification systems can ensure the diameter of any component or product meets its intended dimensions.

For products needing to be supplied within a specific set of dimensions, our laser measurement modules ensure maximum accuracy and consistency.

Our intuitive pressure testing modules can be integrated within a production line to allow pressurised containers such as cannisters or bottles meet the required levels before leaving your line.

Our specialist load testing modules are responsible for ensuring your product meets its design specification by simulating its usage before it leaves your line.

We can support the design and build of your automation system by testing and analysing stress points such as the weight a machine can carry, how much it can flex under pressure, and its durability within certain conditions.

Our experience in automated product testing and inspection

At Sewtec Automation, our in-house capabilities and experience in creating turnkey product testing and inspection systems means we’re the perfect partner for your next project.

Find out more about projects we’ve completed by reading this case study on how track and trace systems help ensure product traceability compliance.