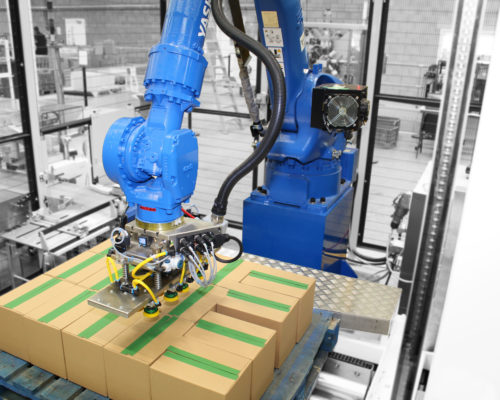

Advanced assembly automation systems

To meet the demands of production rates and processes, manufacturers require automated assembly systems that meet the exact requirements of their products and production lines.

Assembly system automation enables complex assembly processes to be completed in a time efficient manner. For products which require a large number of components, such as medical devices, assembly equipment allows for parts per minute rates to be increased, improving the productivity of a production line.

Flexible assembly systems by Sewtec Automation

At Sewtec Automation, we understand the need for manufacturing production lines to have efficient automated assembly systems.

From continuous motion to linear and rotary formats, we invent, design, manufacture, install, and support assembly systems to enhance the Overall Equipment Effectiveness (OEE), which boosts the production rate and quality of your processes. We have experience in building assembly machines to suit any factory space, handle any cycle time, and meet any mass production requirements, however demanding.

Throughout the design and manufacturing processes, we ensure your assembly system automation are fit for the future. We use the latest technologies to allow your solutions to have longevity and improve your production line in the long term.

We take a modular approach when it comes to building assembly machines to meet your requirements, which allows for greater flexibility. Our modules allow for quick modifications to any production line, acting as building blocks to efficiently move elements in and out to enhance productivity.

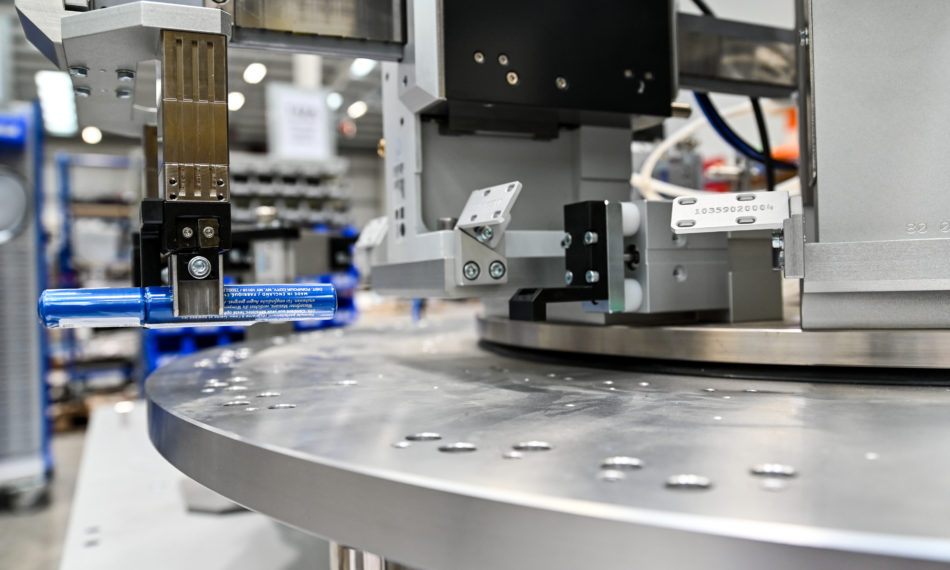

High-performance modules to create automated assembly systems

To enhance production lines and increase productivity, we invent automated assembly with modules using the latest technology.

We use precision link conveyors which offer high levels of speed and accuracy, as well as versatile positioning, high-load capacity, and smooth movement. Our conveyors come either servo or cam box driven.

Our rotary assembly turrets and ring turrets allow for products to be efficiently assembled. This component rotates and indexes to a defined position to allow for a specific part to be assembled.

Our automated assembly systems use intelligent racetracks and specialist software to create a flexible, integrated motion solution. This helps raise production rates, reduce downtime, and increase operational speed.

Using 1, 2, 3 and 4 axis systems, we create auto assembly machines with custom servo-controlled racetracks to allow the speed at which it operates to be controlled.

Our flighted conveyor allows for components and product to be manoeuvred efficiently. These systems enable products to be quickly and gently elevated within your assembly machine.

We use robust and reliable belt and modular conveyor systems in a multitude of ways for most transport applications within an assembly system process. These conveyors are well suited to products without specific positioning or orientation requirements.

For the handling of small, fragile products, our automated assembly machines feature puck-based conveyor systems. This conveyor carries items on a small puck throughout the production line.

Our pallet conveyor systems allow for a single piece flow solution. These conveyors can be modified to suit any sector or production environment.

Our walking beam modules use high performance servo technology to offer a fast transfer system for when other conveyors are not suitable. We build systems which bring high accuracy for a broad range of uses.

Our experience in assembly machine automation

At Sewtec Automation, our in-house capabilities and experience in creating turnkey assembly systems means we’re the perfect partner for your next project.

Find out more about projects we’ve completed by reading this case study on a compact automated assembly machine.