The human side of automation

10 April 2019One aspect of Industry 4.0 - the name given to the current trend of automation and data exchange in manufacturing technologies - that deserves more focus is that there is a very ‘human’ side to automation.

While the common misconception is that automation works independently of humans, the reality is that any manufacturing environment is reliant upon very human non-replicable behaviours and attributes. So, what are some of the characteristics you need to be able to work in automation?

Collaboration and teamwork

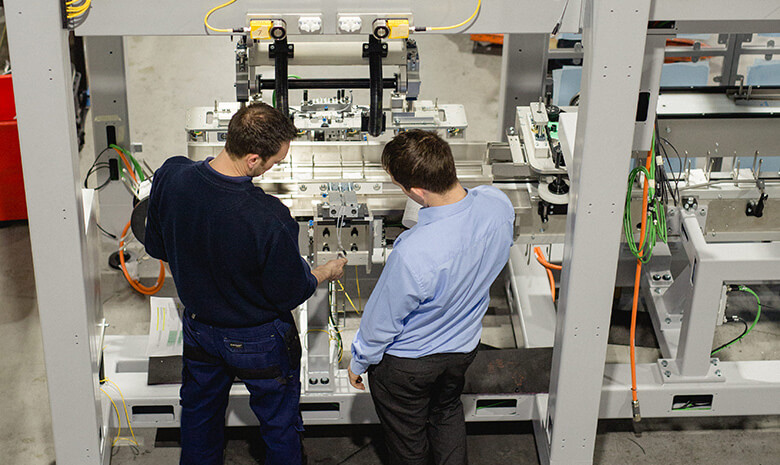

To begin with, anybody working in the automation industry needs to understand the importance of collaboration and good teamwork. Whatever your role or specialism, there’s a huge impetus on working as a team, and it’s crucial that team members are joined-up in their plans and thinking.

Any individual working in automation must be prepared to be involved in regular open and honest discussions across all job roles and departments, especially during the design stage of a project, where designers and mechanical fitters will collaboratively discuss options and solutions to fit the customer brief.

Great communication skills

Such a collaborative approach requires excellent communication and an ability to form good relationships. This applies not only to working with fellow team members, but also with customers and third parties.

Anyone considering a career in automation must have the ability and confidence to communicate effectively and build a good rapport with their client and client team. You should feel comfortable asking questions and prepare to challenge and be challenged.

Understanding what the customer needs

As with the principles applied in modern product development, it’s essential that customer needs are the absolute priority when it comes to designing and building bespoke machinery. Without close collaboration and good communication between bespoke automation solutions provider and customer, the manufacturer could well design what it thinks is a great piece of machinery. But, if it doesn’t fit the needs of the customer, then that same piece of machinery will not be fit for purpose.

The all-important customer brief will define and capture the functional and performance requirements of any system. Analytical skills are critical, as it’s vital that a high level of scrutiny, design and planning is performed up-front to help minimise the risk of unacceptable project slips or inability to meet machine capability requirements.

Buy into the idea of continuous improvement

You’ll need to buy into the idea of ‘continuous improvement’, which, as the name suggests, to continually improve products, services or processes. Emphasising employee involvement and teamwork, it’s a concept that many of the world’s leading organisations fully buy into, as it fosters evolution and innovation. So, if you’re one of those people that likes to fall back on the idea of “but we’ve always done it this way”, then automation isn’t the industry for you.

At Sewtec, we will regularly conduct a ‘lessons learnt’ review to improve future project performance.

You have to love variety

No two projects will ever be the same when it comes to bespoke automation machinery. Medical, confectionary, beverage, bakery, tobacco, pharmaceutical − these are just some of the verticals that we’ve had the pleasure of working with on bespoke automation solution projects. And the robotics and automation industry, of course, has so many potential applications beyond these, from automotive to agriculture to woodworking and aerospace. The possibilities are virtually endless; and so, too, the variety.

If you get excited by the idea of coming up with new solutions for a diverse range of challenges, then automation could well be the career for you.

Roll your sleeves up

Automation isn’t one of those industries you can cruise along in. You really need to be prepared to roll your sleeves up and get stuck in to the varied exciting challenges and opportunities that will be coming your way. You have to apply real passion to everything you do, take a take hands-on approach, and be prepared to keep learning every day.

It’s not just about technical skill

It goes without saying that a design engineer working on bespoke automation solutions will need to have exceptional technical ability and be experienced in using computer-aided design (CAD), computer-assisted engineering (CAE) and computer-aided manufacturing (CAM) software to create prototypes. Similarly, a mechanical fitter will have to be competent and confident in all technical aspects of mechanical engineering, as well as have plenty of experience of precision engineering.

But these aren’t the only qualities anyone looking to work in automation will need. You will need to be enthusiastic, innovatively-minded and willing to throw yourself into any challenge. You’ll have to embrace a working environment where no two days are the same, and have the passion to roll your sleeves up and help solve problems.

And there are plenty of roles in automation beyond the technical ones you would expect, from sales and customer to service and project management.

In all, automation is an incredibly exciting industry to be involved in with people at its heart, whether that be creating new jobs to boost the economy, helping develop new talent in the form of apprenticeships, training for new skills, or building truly collaborative teams with great camaraderie.

Find out more about the exciting career opportunities at Sewtec on our careers page.