Modernisation and upgrades

When it comes to ageing automated machinery and components, manufacturers require a variety of solutions based on their individual challenges.

Planning for obsolescence in automation or machinery

It is important to know when equipment will require updating or repairing before the part itself encounters a fault. Having an obsolescence plan in place where suppliers for spare parts are sourced and equipment is scheduled for upgrades can help manufacturers with budgeting and planned downtime.

Sewtec solution for out-of-date machinery

Even if it appears that a system or machine is obsolete, Sewtec Automation can offer an alternative solution.

Sewtec offers a free consultation of your existing machinery, where an assessment will be carried out to identify the possible opportunities for refurbishment.

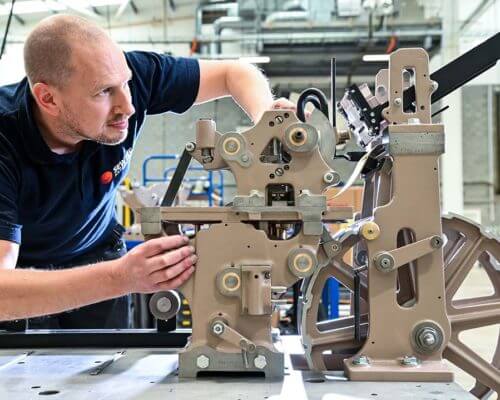

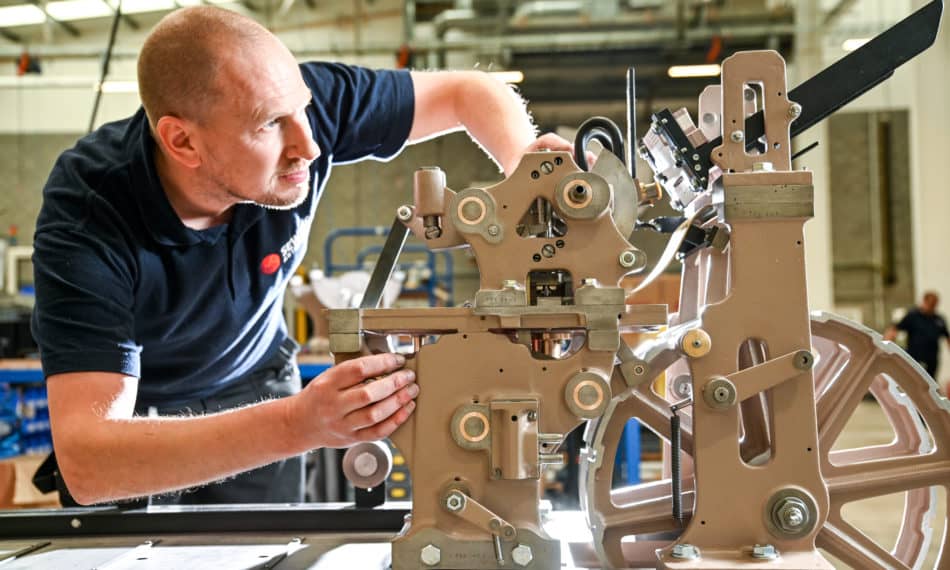

With an in-house technical team and unrivalled engineering excellence, we pride ourselves on renovating and upgrading machines, a challenge that many others cannot or will not tackle.

Our team of engineers will strip out the obsolete parts, replace and upgrade the control system, to get the machinery running like new again.

We also have a track record of enhancing existing machines by carrying out electrical and mechanical improvements, increasing throughput and efficiency, and thereby saving the need for significant investment on new automation machinery.

All refurbished machinery can be CE-marked or UKCA marked before being recommissioned and installed back on site. We can also offer ATEX approved solutions and UL/CSA for the north American market.

The benefits of upgrading automation systems

Opting to refurbish existing machinery is not only a cost-effective solution, but it also benefits the environment by choosing to recycle components and equipment.

When our teams undertake a refurbishment or upgrade of a machine, we can offer service and maintenance packages to ensure your newly refurbished machine continues to run at optimum levels.

Sewtec can replace or refurbish obsolete components of a machine to improve the efficiencies, speed, and Overall Equipment Effectiveness (OEE). Our teams will work with you to capture any new performance requirements, taking into consideration any future alterations in any and all packaging machine services we undertake.

Using the latest CE, PL-d, and UKCA compliance, our teams will upgrade the controls systems of a machine to improve the reliability of real-time performance data. Machine monitoring systems are a future-proof solution to improving your Overall Equipment Effectiveness (OEE). We utilise the latest Industry 4.0 technology to ensure the most accurate and reliable monitoring of your production line.

Our teams can assess all types of equipment, even if Sewtec was not the original manufacturer. Our expertise and experience enable us to reverse engineer automated systems and seek ways to improve the production output.

We have extensive experience with tea bag machine refurbishments from a wide range of manufacturers and can support customers who are looking at machine overhaul options.

Our experts can carry out an on-site evaluation of your current automated system during any of our packing or packaging machine repair services. This allows us to troubleshoot issues and recommend repairs and upgrades, as part of our call-out service.

We offer a build to print service to meet customer specifications. We can also reverse engineer your existing components within your automation production line with our in-house machine and fabrication workshops.

Sewtec Care

Once upgraded your modernised system can be supported through-life by our comprehensive Sewtec Care packages.

Our experience with obsolescence in automation

At Sewtec Automation, our in-house capabilities and experience in working with obsolete machinery means we are the perfect partner for your next project.

Find out more about why obsolescence is not the end for your automated system.